Material Matters: Choosing the Right Plastic for Your Project

- Sep 17, 2025

- 3 min read

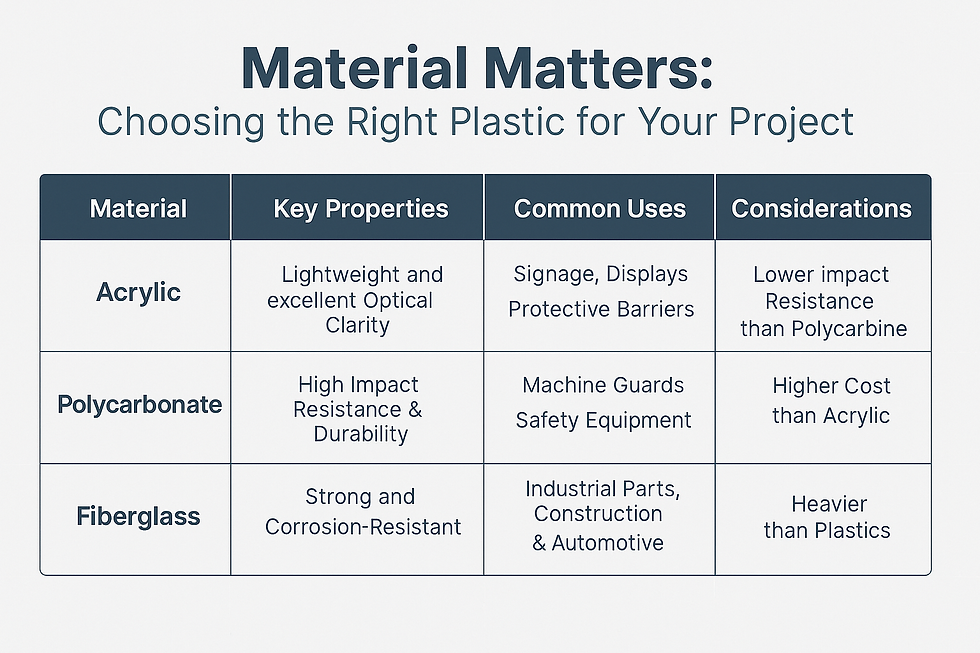

Every successful project begins with one crucial decision: selecting the right material. Whether you’re creating industrial parts, custom displays, or large-scale components, the material you choose will directly impact performance, durability, cost, and aesthetics. For industries ranging from construction to retail, plastics and composites like fiberglass have become essential because of their versatility and strength.

At MGM Plastics, we’ve spent decades helping clients navigate the complex world of materials. As experienced plastic fabricators, we know that the right choice can mean the difference between a product that lasts for years and one that fails prematurely. Here’s our guide to choosing the best material for your project, with insights into plastic fabrication and fiberglass fabrication solutions.

Why Material Choice Matters

Different plastics and composites perform differently under stress, exposure, and environmental conditions. Using a material designed for durability outdoors in harsh sunlight won’t be the same as choosing one meant for lightweight indoor displays.

Factors like temperature tolerance, impact resistance, weight, and appearance should all be considered. Experienced plastic fabricators can help you evaluate these elements and guide you to the most effective solution for your unique project.

Common Plastic Options

Acrylic

Acrylic is lightweight, crystal-clear, and often used as a glass alternative. It’s perfect for signage, retail displays, and protective barriers. Acrylic can be polished to a high gloss and shaped through heat forming. While not as impact-resistant as some alternatives, its clarity and versatility make it a popular choice in plastic fabrication.

Polycarbonate

If impact resistance is a priority, polycarbonate is the go-to choice. It’s virtually unbreakable and is often used in safety shields, machine guards, and security applications. Though it’s more expensive than acrylic, its durability pays off in demanding environments.

PVC

PVC is strong, lightweight, and cost-effective, making it a common choice for piping, construction, and industrial applications. It’s resistant to chemicals and moisture, and it machines well, which makes it attractive for a wide variety of projects.

ABS

ABS combines toughness with a lightweight feel. It’s often used for enclosures, automotive components, and consumer products. ABS can be easily machined or thermoformed, offering flexibility in design.

Fiberglass: A Strong Alternative

While plastics are incredibly versatile, some projects demand even more strength and resilience. That’s where fiberglass fabrication comes in. Fiberglass is a composite material made from woven glass fibers reinforced with resin.

Key benefits of fiberglass include:

High strength-to-weight ratio: Stronger than many metals but significantly lighter.

Durability: Resistant to corrosion, chemicals, and weathering.

Versatility: Can be molded into complex shapes for industrial, automotive, and architectural applications.

At MGM Plastics, our fiberglass fabrication services support industries that require reliable, high-performance parts that stand the test of time.

How to Choose the Right Material

When evaluating materials, keep these key considerations in mind:

Environment: Will the part be used indoors or outdoors? Exposure to UV light, heat, or moisture may influence your choice.

Durability Needs: Do you need impact resistance, chemical resistance, or structural strength?

Weight: Is lightweight performance critical, such as in aerospace or transportation applications?

Aesthetics: Does the project require optical clarity, a polished finish, or custom colors?

Cost: Balancing budget with performance ensures you get the best return on investment.

By weighing these factors, you can narrow down your material options and make a confident choice.

The Role of Expert Fabricators

Selecting the right material is just the first step. Experienced plastic fabricators bring design expertise, precision cutting, and finishing capabilities to ensure your project meets its goals. At MGM Plastics, we don’t just provide plastic fabrication services—we partner with clients from concept through completion to ensure materials and processes align with project requirements.

Our ability to work with a range of materials, including acrylic, polycarbonate, PVC, ABS, and fiberglass, allows us to provide tailored solutions for projects of all sizes and complexities.

Final Thoughts

The materials you choose define the success of your project. Whether it’s the clarity of acrylic, the toughness of polycarbonate, or the unmatched durability of fiberglass fabrication, understanding your options is the first step toward achieving your goals.

At MGM Plastics, we combine decades of expertise with advanced equipment to deliver the results you need. From high-quality plastic fabrication to durable fiberglass fabrication, we’re the plastic fabricators businesses across San Diego and beyond rely on.

Ready to select the right material for your project? Contact MGM Plastics today to speak with our team of experts and discover the best solution tailored to your needs.

.png)

Comments